When you need to protect what matters most, you can trust bulletproof fiberglass to withstand ballistic impact.

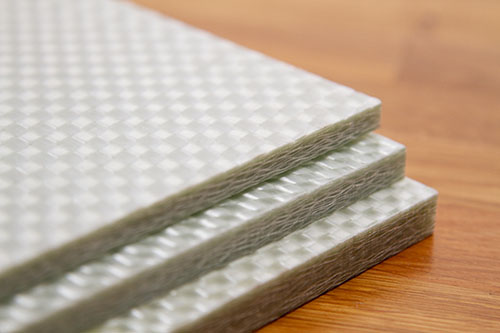

Also referred to as bullet-resistant or ballistic fiberglass, these panels are made of reinforced structural polyester laminate and can withstand extreme impact.

Ballistic fiberglass panels can be used anywhere there is the potential for an assault. Businesses and facilities like financial institutions, courtrooms, police stations, prisons, convenience stores, check-cashing businesses, and more use bullet-resistant panels to safeguard against intrusion and ballistic attacks.

Jump To:

How Panels Keep You Safe | Specifications | Custom Panels

How Our Bulletproof Fiberglass Panels Keep You Safe

Our bulletproof fiberglass panels are made from a combination of fiberglass and resin. Panels are cured using heat and pressure, creating an incredibly strong woven material. When fired upon, this material “catches” a bullet by absorbing its energy within the tightly-woven layers. The result is a controlled event with no spalling or penetration through to the secure side.

Common Applications for Ballistic Panels

Where there’s a threat, there’s an application for bulletproof fiberglass. Reinforce virtually any area, including, but not limited to:

- Booths and entry vestibules

- Reception areas

- Conference rooms

- Podiums and desks

- Countertops

- Walls

- Safe rooms and panic rooms

Want to reinforce existing areas? No problem. In addition to new construction projects, we can retrofit ballistic panels to blend perfectly with your space and your aesthetics.

Ballistic Fiberglass Is Available in a Variety of Strengths

Our selection of bulletproof fiberglass panels protects against impact from a bullet, blast, or forced entry. Products are tested according to UL-752 and ASTM E 119 standards.

| UL Rating |

Weapon | Ammunition | Weight | Velocity | Shots | Typical Uses | Ballistic Material Thickness |

|---|---|---|---|---|---|---|---|

| 1 |  |

|

124 grains 8 grams |

1175 FPS to 1293 FPS |

3 | Gas stations Banks Pharmacies Retail Shops |

L1 Glazing: 0.5”–1.25” L1 Fiberglass: 0.25” Armor Plate: 0.25” |

| 2 |  |

|

158 grains 10.2 grams |

1250 FPS to 1375 FPS |

3 | Corporate Banks Financial Institutions |

Glazing: 0.75”–1. 375” Fiberglass: 0.375” Armor Plate: 0.25” |

| 3 |  |

|

240 grains 15.6 grams |

1350 FPS to 1485 FPS |

3 | Utilities Police Stations Government Facilities |

Glazing: 1.25” Fiberglass: 0.5” Armor Plate: 0.25” |

| 4 |  |

|

180 grains 11.7 grams |

2540 FPS to 2794 FPS |

1 | Federal Government Military |

Glazing: 1.5” Fiberglass: 1.375”” Armor Plate: 0.25” |

| 5 |  |

|

150 grains 9.7 grams |

2750 FPS to 3025 FPS |

1 | Federal Government Military |

Glazing: 1.625” Fiberglass: 1.375” Armor Plate: 0.3125” |

| 6 |  |

|

124 grains 8 grams |

1400 FPS to 1540 FPS |

5 | Federal Government Military |

Glazing: 1.25” Fiberglass: 0.5” Armor Plate: 0.25” |

| 7 |  |

|

55 grains 3.56 grams |

3080 FPS to 3388 FPS |

5 | Federal Government Military |

Glazing: 2. 1875” Fiberglass: 1.625” Armor Plate: 0.25” |

| 8 |  |

|

150 grains 9.7 grams |

2750 FPS to 3025 FPS |

5 | Federal Government Military |

Glazing: 2.5” Fiberglass: 1.625” Armor Plate: 0.3125” |

| 9 |  |

|

1 | Federal Government Military |

|||

| 10 |  |

|

1 | Federal Government Military |

Choosing Your Level of Ballistic Protection

When you’re concerned about external threats, the highest level of protection might seem like the natural best option. However, most shootings and crimes involving firearms are committed with handguns. Levels 1 through 3 protect against handgun fire and are often sufficient protection for most applications. Of course, there are always exceptions based on your unique circumstances. Our team has helped all kinds of businesses secure their facility with ballistic panels and we are ready to walk you through the decision-making process. To get started, give us a call at 916.373.0402 or send us a message.

Bullet-Resistant Fiberglass Panel Specifications

| Item # | UL 752 Protection Level | Thickness | Weight | Flat Sheet Sizes Available |

| BGAA-01 | Level 1 | 1/4″ | 2.6 lbs/sq. ft. | 4′ x 8′ |

| BGAA-02 | Level 2 | 5/16″ | 3.6 lbs./sq. ft. | 4′ x 8′ |

| BGAA-03 | Level 3 | 7/16″ | 5 lbs./sq. ft. | 4′ x 8′ |

| BGAA-04 | Level 4 | 1 3/8″ | 14 lbs./sq. ft. | 3′ x 8′ minimum 5′ x 9′ maximum Special Cut |

| BGAA-05 | Level 5 | 1 7/16″ | 15 lbs./sq. ft. | 3′ x 8′ minimum 5′ x 9′ maximum Special Cut |

| BGAA-06 | Level 6 | 7/16″ | 3.9 lbs./sq. ft. | 3′ x 8′ minimum 5′ x 9′ maximum Special Cut |

| BGAA-07 | Level 7 | 1 1/8″ | 12 lbs./sq. ft. | 3′ x 8′ minimum 5′ x 9′ maximum Special Cut |

| BGAA-08 | Level 8 | 1 7/16″ | 15 lbs./sq. ft. | 3′ x 8′ minimum 5′ x 9′ maximum Special Cut |

Customize Bullet-Resistant Fiberglass Panels

Compared to traditional bullet-resistant building materials (such as plate steel, concrete, or cinder blocks with sand), bulletproof fiberglass offers an exceptional level of customization and utility in a lighter weight and more compact solution.

Ballistic fiberglass is lightweight and can be easily cut, drilled, sanded, painted, or textured. Ballistic fiberglass panels can be primed and painted with oil or water-based paints. They can also be glued to other surfaces with adhesives as well as covered with drywall, wood panels, or any other type of wall covering.

Bulletproof Fiberglass Installation Tips

- Use the Right Tools

When installing, we recommend cutting bulletproof fiberglass using a carbide tip blade in a circular saw or a jigsaw. We also recommend pre-drilling holes for fastening your materials to a substrate. - Wear Protective Gear

Cutting fiberglass can produce a large amount of dust. If you need to cut the material, be sure to wear eye and respiratory protection. - Carefully Measure Drilling Depth

Always pre-measure your drilling depth. It’s possible to drill through the fiberglass on accident; measuring helps avoid any irreversible damage. - Screw From Below

Instead of screwing from the top down when you’re installing a bulletproof countertop, screw from underneath up. Always measure first to avoid putting a hole through the countertop. - Avoid Cutting Ballistic Fiberglass

When you can, avoid cutting fiberglass materials on-site. Some fiberglass panels are capped with laminate on the ends for aesthetic purposes and should not be cut. Check the documents that came with your order for specific details about your project.

Bullet Guard Is Your Trusted Bulletproof Fiberglass Panel Provider

No matter what your industry or application, Bullet Guard has the expertise and expertise to design, fabricate, and install the bulletproof solution you’re looking for. If you have questions about the process or would like to learn more about our bulletproof fiberglass products, please reach out to us for more information. We look forward to hearing from you!